RZFD-330D

Properties and uses

This machine is used for roll raw color paper or printing roll paper such as Kraft paper food paper and other paper rolls. This machine completes the paper bag process at one time. By automatic paper roll tension control system roll correction patch bag positioning gluing pasting patch automatic center gluing raw material into into the shape of the barrel open the hole of patch bag fixed long cut bottom indentation bottom folding bottom gluing bottom forming finished bag collection paper bags completed at one time. Operation is more convenient more efficient more stable.It could produce a variety of different paper bags like leisure food bags bread bags dry fruit bags and other environmentally friendly paper bags.

MTED Advantages

1. Use France SCHNEIDER touch screen human-computer interface making the machine easy to operate and control.

2. Adopt Germany original LENZE PC controller integrated with optical fiber. Thus ensure stable and high speed running.

3. Adopt Germany original LENZE servo motor and German original SICK photoelectric eye in correction tracking the size of printing bag accurately.

4. Patch bag function adopts a complete set of German original LENZE servo motor. Through integration with optical fiber it works with the German original REXROTH motion controller (PC).

5. Automatic hole-punching adopts Germany original LENZE servo motor.

6. Raw material loading adopts hydraulic auto-lifting structure. Unwind unit adopts auto tension control.

7.Use Italy SELECTRA material edge rectify system substantially cut off the edge alignment time.

Technical parameter

| Model | RZFD-330D |

|

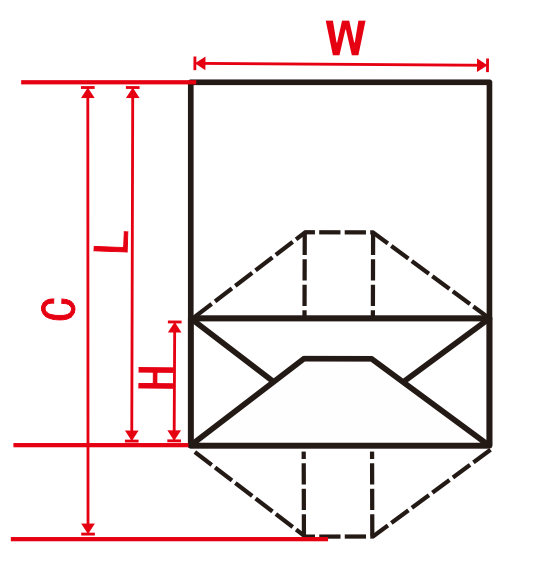

| Cutting length | 270-530m | |

| Bag width | 120-330mm | |

| Bottom width | 60-180mm | |

| Paper thickness | 80-150g/㎡ | |

| Machine Speed | 30-220pcs/min | |

| Paper bag speed | 30-200pcs/min | |

| Patch Bag width | 190-330mm | |

| Patch Handle length | 75/85mm | |

| Paige bag paper thickness | 80-150g/㎡ | |

| Paige bag film thickness | 40-70µm | |

| Paige bag roll width | 130mm | |

| Paige bag roll straight | 500mm | |

| Patch Bag speed | 30-130pcs/min | |

| Paper roll width | 450-1050mm | |

| Roll paper diameter | φ1200mm | |

| Machine power | 3phase 4 wire 380V 40.58kw | |

| Machine weight | 11800kg | |

| Machine size | 16000x2200x2600mm |